1 min read

Quality control for medical ceramics - safety in production

‘Health is the first duty in life’, as Oscar Wilde aptly remarked. The use of technical ceramics for implants has become indispensable as a medical...

When pressing powders, both ceramic and metallic materials, the density of the pressed body determines its mechanical properties such as strength and hardness. A higher density reduces porosity, improves particle bonding and minimises weak points in the material. This leads to more robust and durable end products. Density is therefore the decisive criterion for production.

The parameterisation of the presses includes the setting of pressure, speed and holding time. These parameters have a direct influence on the density and quality of the pressed body. After each feedstock change, the presses must be taught in again and adapted to the changing conditions, as the shrinkage behaviour can change depending on the interaction of these factors with the respective feedstock.

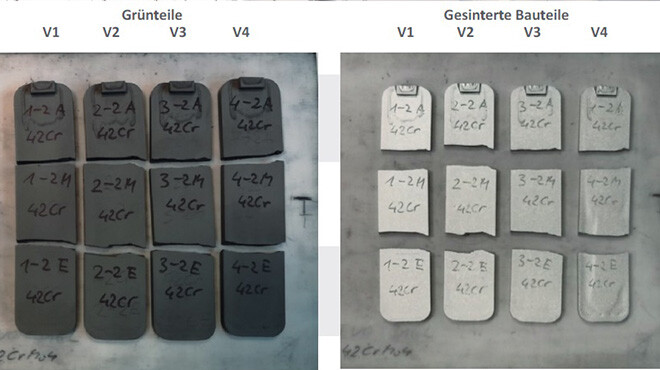

Test pressings are used for this purpose, in which test specimens are pressed, sintered and then compared in order to analyse the existing shrinkage. To simplify this process, the direct correlation of green density and shrinkage can be considered, which makes the shrinkage behaviour predictable.

The density of the green compact is a critical indicator of the shrinkage behaviour during sintering. As the density changes during sintering, it is important to know the shrinkage dimension of a component in order to ensure the optimum quality of the end product.

Accurately determining the density of the green compact makes it possible to calculate the shrinkage dimension and make appropriate corrections to avoid dimensional deviations before sintering. A precise density value therefore helps to optimise the pressing process and adjust the settings of the pressing machines accordingly.

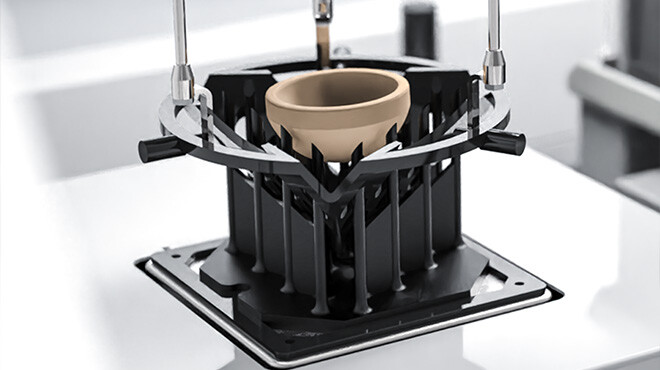

In order to make the process valid and effective, the density of green parts must be determined precisely and quickly. Automated density determination according to Archimedes offers this combination and allows repeatable measurement results to be achieved directly in the production environment.

By automating the measurement process, the density of water-drawing components can be analysed without pre-treatment and non-destructively. The measured values can be used to provide precise information about the shrinkage dimension and possible process errors can be determined before the sintering process.

The density in the moulding process of pressing ceramic and metallic powders is the decisive factor that strongly influences the quality and properties of the end products. By precisely determining the density of green parts, the parameterisation of the pressing machines in production processes can be optimised and high-quality products can be manufactured. This is particularly important for applications in high technology, where maximum precision and reliability are required.

Quelle: Analyse von Messverfahren zur Dichtebestimmung - Fraunhofer IAPT - Dimensionics Density GmbH

1 min read

‘Health is the first duty in life’, as Oscar Wilde aptly remarked. The use of technical ceramics for implants has become indispensable as a medical...

What awaits you here: INTRODUCTION TEST SETUP AND IMPLEMENTATION RESULTS OF DENSITY MEASUREMENT OPTIMISATION OF PRODUCTION PARAMETERS CONCLUSION AND...

What awaits you here: INTRODUCTION MICROGRAPH COMPUTERTOMOGRAPHY (CT) AUTOMATED DENSITY DETERMINATION CONCLUSION Introduction In additive...