Which method is the right one?

Density determination for CIM & MIM components

The future of density determination

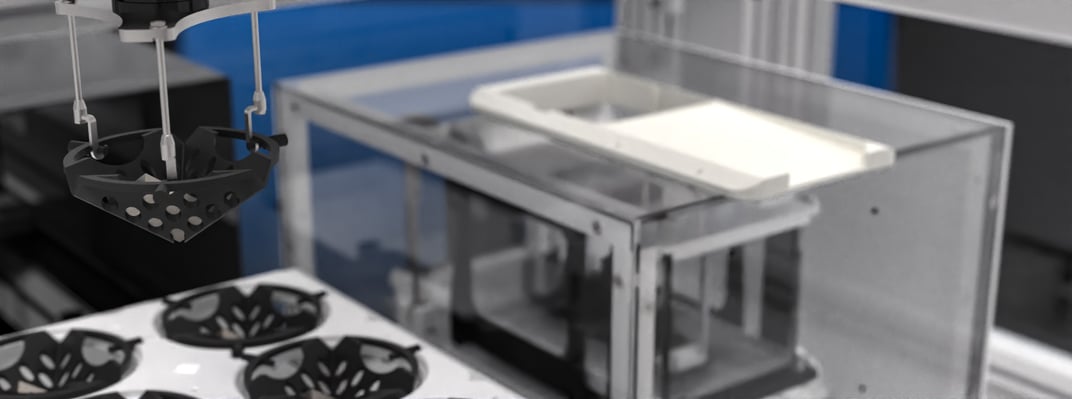

The measuring system is designed for operation in a production environment. Thus, it is not limited to use in a laboratory environment, as is usually the case. Due to the fast execution of the density measurement and the possibility to integrate the system into the production line, sufficiently short reaction times are possible for the first time to adjust process parameters if necessary.

Manually rethought

The shorter the reaction time, the lower the amount of potentially produced rejects. The fully automated density measurement system from Dimensionics Density GmbH enables reproducible, highly accurate measurement primarily by:

- Exclusion of human influence factors by means of fully automated component handling

- Recording of all relevant environmental factors (water and air temperature, ambient pressure, air humidity)

- Avoidance of external disturbances (vibrations, air circulation, heat radiation) through enclosure and mechanical decoupling.

- Maintaining constant measuring conditions during wet weighing by regulating the level and an automated liquid change.

The elimination of human influence is the greatest advantage of automated density determination. As an alternative to the manual Archimedes method, micrographs and micro-CT are used to examine the components. Both systems have advantages and disadvantages. For a detailed examination of the internal structure of a green part, both methods are suitable. For optimised process monitoring and rapid parameterisation of tools, both methods are too time-consuming and also tie up valuable personnel resources.

The ability to react quickly and economically in a production process is only possible by integrating the test method into the production environment. The Dimensionics Density platform is based on the Archimedean principle, but overcomes the disadvantages of typical laboratory density determination technologies based on the Archimedean principle and develops a solution that really measures density and does so directly in production.

Alternative methods

Which methods exist besides the automated density determination by the Density Platform? We offer a brief overview and list the

advantages and disadvantages of the respective systems.

Micrograph analysis is a method for the qualitative and quantitative description of the microstructure of materials. The sample/component is segmented and the surface of the cut surface is prepared by mechanical and chemical methods. This is followed by a microscopic

analysis of the component.

Advantages:

- High-precision process

- Results provide clear conclusions about process errors

Disadvantages:

- High effort in the preparation of micrographs (ties up personnel)

- resulting waiting times

- Not optimal for effective process handling

In computed tomography (CT), the specimen is exposed to X-rays. The density influences the brightness of the exposed imaging sensor. X-rays are absorbed during transmission through the material; this absorption is stronger at higher densities of the material. If an X-ray beam hits a pore during transmission through the material, the energy is absorbed less due to the lower density within the pore. Therefore, the radiation hits the detector with a higher energy and produces a darker image. By using a three-dimensional exposure strategy, it is possible to determine the shape and position of the pores.

Advantages:

- Precise three-dimensional representation of pores and pore clusters in the component

- Expression, accumulation and shape of pores can be analysed

Disadvantages:

- High initial investment

- Use of trained personnel required

- Microporosities no longer recognisable due to resolution limit

- Waiting times due to post-processing of raw data to eliminate artefacts in the image.

Density determination according to Archimedes is one of the most common methods in many industries. Density kits, special laboratory balances with a suitable measuring set-up, are used for this. The sample is then weighed in air and in a defined liquid. The density of the component is determined from the difference.

Advantages:

- Fast analysis method

- Archimedes highest accuracy according to studies

Disadvantages:

- Strong human influence (skilled workers needed)

- Measurement only in the laboratory (long distances)

- Unsuitable for high quantities

During optical density determination, the dimensions of the object to be tested are recorded in their entirety and the volume is determined. This is followed by weighing for mass determination and the resulting density determination of the component.

Advantages:

- fast method for density determination

- very well suited for simple and regular geometries

Disadvantages:

- Dependent on the resolution of the sensors

- high acquisition costs

- Unsuitable for the analysis of complex geometries